Mechanically Stabilized Earth (MSE) Wall Preserves Access to New Zealand Beach

THE CHALLENGE

The popular Harrisons Cut carpark and boat ramp was battered by a significant spring storm event in August 2018, compromising a vital live drain and threatening the stability of nearby dunes and the adjacent access road, parking area, and pedestrian walkway.

THE SOLUTION

Three interlocking Redi-Rock mechanically stabilized earth (MSE) walls shored up the infrastructure and bolstered the drain, and the rugged Ledgestone face texture integrates beautifully with the surrounding area. Planter blocks were also incorporated to host native vegetation, completing the natural look.

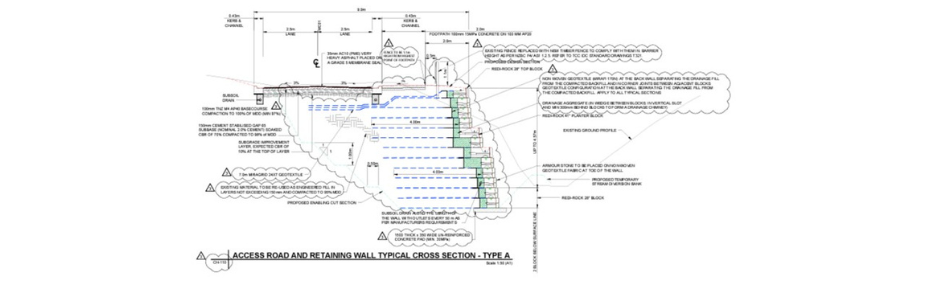

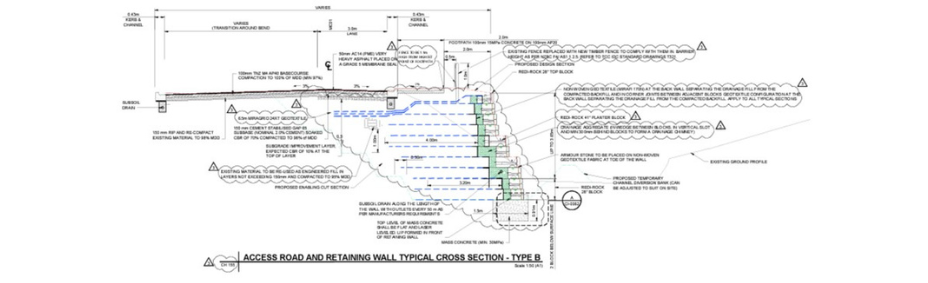

The Design

The project was scheduled for the region’s winter season to limit its impact on site usage. While this decision ensured access to the site during the prime summer season, winter weather necessitated dewatering and diverting of the live drain. An initial proposal to cast the retaining wall on-site was abandoned when cast-in-place was deemed incompatible with the location’s wet conditions and too costly.

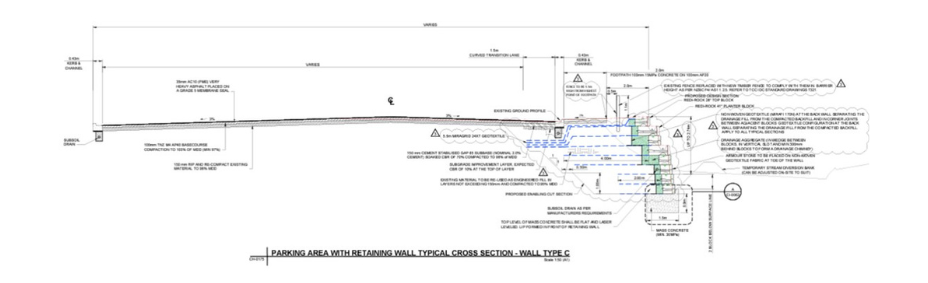

Additionally, the proximity of the roadway, pedestrian pathway, and carpark demanded consideration of load-bearing requirements as potential wall solutions were evaluated. These surfaces necessitated a new design of the stormwater handling network and its integration with the retaining wall system.

New Zealand-based Redi-Rock manufacturer Duracrete Products has supplied numerous high-profile projects in the region, including several urgent infrastructure repairs made necessary by significant storm activity. As a result, project owner Tauranga City Council (TCC) and the project’s engineering firm, AECOM, were familiar with the Redi-Rock engineered retaining wall system. Both parties were confident Redi-Rock’s design versatility, performance in and around water, straightforward installation, and visual appeal made it the best choice for this project. “Aesthetically, Redi-Rock looks fantastic,” said Gareth John, TCC’s project manager for city waters. “And once the contractor gets into a rhythm, they’re easy to install.”

Redi-Rock’s dozens of precast block options work together seamlessly to create durable long-term solutions, which allowed AECOM to propose a series of three interlocking reinforced walls to address the project’s differing site conditions and load demands.

The Installation

Redi-Rock 28-in (720-mm) Positive Connection (PC) Middle blocks comprised the majority of the wall sections, which varied in height from 7.5 ft (2.29m) up to 15 ft (4.57m). Depending on site conditions, Redi-Rock MSE walls can achieve heights exceeding 50 ft (15m) with the installation of geogrid or earth anchors behind the wall. PC Middle blocks feature a patented knob and groove technology and include a center core slot cast directly into the block allowing for 12-in (300-mm) wide strips of PVC-coated polyester yarns - or biaxial geogrid - to wrap through the slot and extend into the reinforced fill zone.

Geogrid strips also allow for enhanced flexibility when navigating behind-the-wall utilities or stormwater and drainage infrastructure, as was the case with this project.

To ensure proper handling of water runoff from the roadway, carpark, and walking path, drainage backfill was used to a distance of 300 mm (12 in) directly behind the blocks. Two manholes were also installed, connected to stormwater outlet pipes exiting the retaining wall at the second course, extending past the face, and resting on the block below.

Threaded rebar rods, steel plates, and nuts were placed into the wedge between blocks, anchoring the manhole’s underground enclosure to the retaining wall. More strength was added by the inclusion of hooked threaded rods specially cast into the Redi-Rock blocks and secured to the enclosure with steel flange nuts.

![RR_PC_Duracrete_Harrisons-Cut_Finished_9_1-Column_[Landscape]_928x283.jpg](https://aster-brands.imgix.net/redi-rock/RR_PC_Duracrete_Harrisons_Cut_Finished_9_1_Column_Landscape_928x283_a7177a9c5c.jpg)

The versatility of the Redi-Rock system is on full display when something more than just a wall is required. Conveying water or utilities through a wall with conduit can be accomplished with ease and minimal additional engineering in most cases.

“Redi-Rock is an excellent product that was selected for its durability, constructability benefits, and overall aesthetics. I would recommend it to anyone and would use Redi-Rock again on future projects.”

Gareth John, Tauranga City Council Project Manager: City Waters

The Outcome

Harrisons Cut is a popular regional recreation destination that prompted the TCC to specify a retaining wall as attractive as it was functional. It was paramount that the solution be visually appealing upon its completion. This led to the selection of Redi-Rock’s deeply detailed Ledgestone texture, which finishes with a random, stacked stone appearance. Ledgestone features up to 10 individual face molds, offering up to 113 sq ft (10.5 sq m) of non-repeating pattern.

To further enhance the appearance of the wall, two rows of 41-in (1030-mm) Redi-Rock planter blocks were incorporated to host native vegetation. The project utilized 96 of these planter blocks, which offer setbacks up to 16.6 in (422mm) – the system’s largest batter option available – and can be integrated seamlessly with any Redi-Rock project to add both depth, detail, and design to the wall’s face.

![RR_PC_Duracrete_Harrisons-Cut_Finished_12_1-Column_[Landscape]_928x283.jpg](https://aster-brands.imgix.net/redi-rock/RR_PC_Duracrete_Harrisons_Cut_Finished_12_1_Column_Landscape_928x283_e13745809f.jpg)

Excepting a few minor future enhancements like seating and an adjacent boardwalk, the Harrisons Cut Beach Accessway project was completed in December 2022. The installation of the retaining wall and boat launch, and the upgrades to the access road, walking path, and carpark were budgeted for NZD$3.35 million but the project’s main components finished with a savings of nearly NZD$700,000. Understandably, the TCC was pleased with the finished project and the construction process. “The team managed to deliver in time for summer as planned, while keeping under budget,” concluded TCC waters manager, Radleigh Cairns.

The before-and-after images of Harrisons Cut tell the story of a live drain and adjacent infrastructure at risk of failure, rescued by a rock-solid MSE wall as eye-catching as it is reliable.

Ultimately, the TCC’s John believes the Redi-Rock solution was the perfect fit for the important project. “Redi-Rock is an excellent product that was selected for its durability, constructability benefits, and overall aesthetics. I would recommend it to anyone and would use Redi-Rock again on future projects.”

Products Featured

Positive Connection (PC) Wall Blocks - Build MSE retaining walls with the revolutionary Redi-Rock Positive Connection (PC) blocks.

Planter Blocks - Offering the largest batter option available in the Redi-Rock system, Planter Blocks extend the setback up to 16.6 in (422mm).

Ledgestone Texture Blocks - Redi-Rock’s Ledgestone texture gives projects a random, stacked stone look.

Related Resources

Will Redi-Rock Work in Water? Yes!

When it comes to water, not all retaining wall solutions are created equal. Download the Water Application Guide to see how Redi-Rock stacks up in eight different water scenarios.

Build Taller. Support Larger Live Loads

Redi-Rock reinforced walls can help achieve wall heights over 50 ft (15m) and support massive live loads. Read more about how reinforced walls can make a difference in your project.

UK Marina Wall Stands Up to Irish Sea Storms

Looking for another example of how Redi-Rock can weather the worst Mother Nature can throw at it? Check out the Foryd Harbour Enhancement Project #160 in Rhyl, North Wales.